HOW TO RECLAIM UP TO 30% MORE OF YOUR CERAMICS MEDIA

// 11/2/2019 12:00:00 PM

During the process of manufacturing paints or other coatings, one of the steps involved is milling or grinding all of the dry ingredients into the liquid portion of the paint. These dry or solids consist of Titanium Dioxide (TIO2) pigments, binders, and various other powders. The liquid portion is mainly solvent or in the case of latex base – water. Once all of these dry ingredients have been thoroughly mixed (the proper term is dispersed) into the liquid base of the paint, the next step involves a high shear, high energy process called media milling.

In a nutshell, the paint is run through a chamber that has an enclosed horizontal shaft with discs or blades. The chamber is also filled with very small, spherical, grinding media. The media is made of different materials such as glass, steel, and ceramic media. The mixture of liquid and dry ingredients are then passed through the chamber filled with grinding media. The purpose of the media is to ensure that all the liquids and solids are thoroughly reduced to the smallest particle size possible by “grinding” the particles to achieve material size satisfaction. Over time, the end result of this process is grinding media that has been either reduced in size or recycling broken media. In turn, this media becomes more and more inefficient in the milling process.

Many types of grinding media can be very expensive. Advances in the quality and fine size range of ceramic media have caused the price to rise substantially and the price to fill a chamber is quite costly. As the grinding media wears, it reduces in size or cracks in pieces so periodically this media needs to be thrown out and replaced. While much of the media is still reusable, it is next to impossible to remove the bad media from the good material. This is where HK Technologies’ equipment comes into play.

We offer a vibratory screening process that allows for the media mill operator to simply dump his cleaned grinding media into our vibratory screener – Our Model HKC17. The HKC17 has two screen decks. The first deck will remove any debris such as old gaskets, clumped media, or other debris. The second deck will remove the worn, cracked, or broken media. This leaves the “good” material on top of the screen and then discharges off the top of the screen deck into a container. This material is now ready to be reused. Since there are many different sizes of media, the operator will need to have the proper mesh or screen size. For instance, a 20 mesh screen will retain any media larger than 20 mesh and let pass any smaller or worn media.

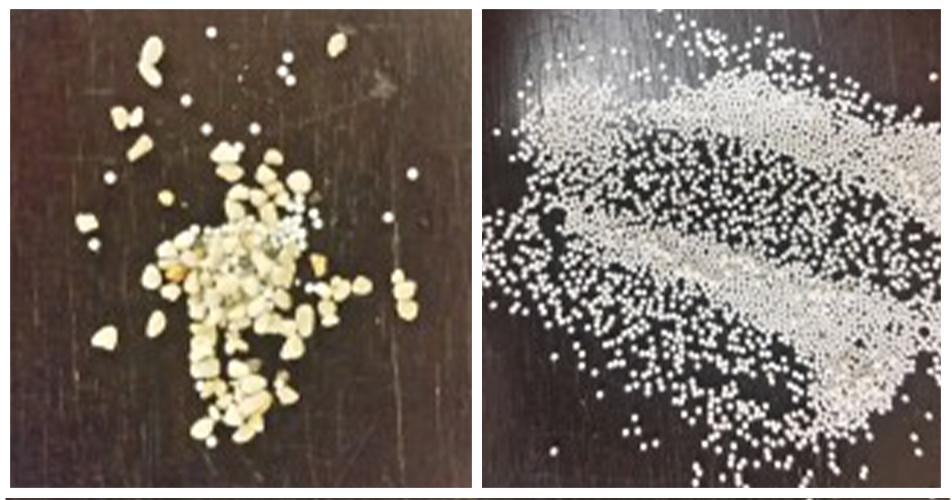

Below are a couple of pictures of media that have been screened through our Model HKC17. This particular customer was able to retain 30% of his media. Prior to the use of the HKC17 to reclaim media the customer simply threw out the used media. With a 30% savings, the HKC17 will pay for itself in a short period of time.

Want to learn more about our Ceramics media screening technologies? Contact us today!